Plasma Technology in Action – Live at PCIM Europe 2025

Power modules are the core of modern power electronics – whether in e-mobility, industrial automation, or renewable energy applications. From May 6–8, 2025, Plasmatreat will be showcasing how plasma technology can significantly enhance the performance and reliability of these critical components at PCIM Europe in Nuremberg.

At booth 169 in Hall 7, we’ll demonstrate live how oxide layers can be removed automatically and inline, and how our PlasmaPlus® coating technology effectively prevents delamination during overmolding. Visit us on-site and discover what future-ready surface treatment looks like – precise, cleanroom-compatible, and environmentally friendly.

Challenges in Semiconductor and Power Module Production

Tough Demands on Materials and Interconnections

High-performance power modules must operate reliably for years under extreme conditions. Whether in electric vehicles, wind turbines, or industrial drives, these components are exposed to high temperatures, high voltages, and intense mechanical stress – all within increasingly compact designs.

A particular challenge lies at so-called “triple points,” where different materials such as copper, ceramics, and potting compounds meet. These zones are prone to stress, trapped air, or adhesion failure – all of which can shorten the module’s lifespan. One of the root causes: oxidized metal surfaces that compromise solderability and increase contact resistance. Epoxy delamination during overmolding is another common risk. To address these issues, reliable interconnect technology and targeted surface treatment are essential.

Live Demo at PCIM Europe

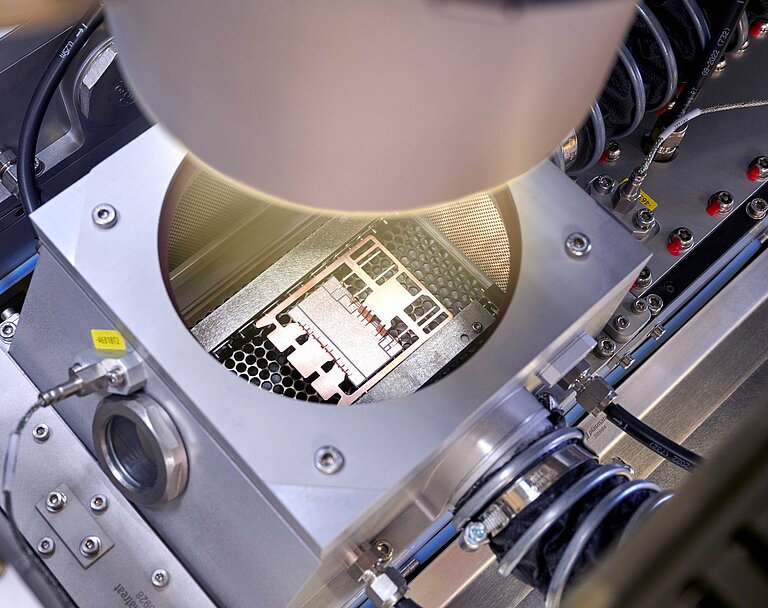

Experience our plasma technology live at booth 169 in Hall 7. In a fully automated demo cell, we’ll showcase both REDOX-based inline oxide reduction and functional nanocoating with PlasmaPlus® – all under realistic production conditions.

A highlight of our exhibit is the robot-controlled Plasma Treatment Unit (PTU), which allows for accurate, non-contact treatment of even complex geometries. At our interactive plasma demonstration table, you can see and feel the effects of plasma treatment for yourself – from surface cleaning and activation to improved wettability.

Our on-site experts are available to advise you on how our technologies can be tailored to your specific applications and processes.

Use Cases – Where Plasma Makes the Difference

Application Areas Across High-Demand Industries

Our plasma systems are used wherever power modules are exposed to extreme conditions and need to perform reliably. Different industries face different challenges – but the solution remains the same: advanced surface treatment with Openair-Plasma® and PlasmaPlus®.

E-Mobility

In inverters, battery management systems, and charging units, plasma ensures stable electrical contacts and prevents delamination in highly dynamic environments with intense heat and current loads.

Renewable Energy

Photovoltaic and wind energy systems require long-term durability despite exposure to UV radiation, moisture, and temperature swings. Plasma coatings help protect critical contact areas and improve reliability.

Industrial Automation

Power modules in industrial and robotic systems must withstand vibration, dust, and harsh media. Plasma treatment improves adhesion of potting compounds and ensures long-lasting, high-integrity connections.

The Exhibition Warm-Up: Power Module PlasmaTalk Now Online

主要工艺挑战包括:

助焊剂残留物

- 污染:助焊剂残留会污染组件,导致电气短路、腐蚀和可靠性问题。

- 清洁工艺难题:随着元件小型化、高度密集,在不损坏元件的情况下清除助焊剂残留物变得越发困难。

微型化

- 精度要求:更微型的元件和更细小的间距需要极其精确的制造工艺。即使是微小的瑕疵也会导致严重的性能问题或故障。

- 散热:随着元件尺寸的减小,高效散热变得更具挑战性,这就需要高质量的焊点和材料来有效管理热量。

长期可靠性

- 环境条件:电子电气设备经常暴露在高温、潮湿和振动等恶劣环境中。确保所有材料和焊接处无空隙和缺陷对于保持长期可靠性至关重要。

- 老化及退化: 随着时间的推移,材料会发生老化,接头也会减弱。空隙和缺陷会加速这一过程,导致早期故障。

应对工艺挑战

Openair-Plasma®等离子技术和REDOX®-Tool在线氧化还原等技术可以有效地清洁和预处理表面,确保所有材料即使在电子产品的高工艺要求下也能正常粘合并可靠运行。

该技术能改善电气性能,提高成品率,并增强元件的整体可靠性和使用寿命。