Plasma Technology in Action – Live at PCIM Europe 2025

Power modules are the core of modern power electronics – whether in e-mobility, industrial automation, or renewable energy applications. From May 6–8, 2025, Plasmatreat will be showcasing how plasma technology can significantly enhance the performance and reliability of these critical components at PCIM Europe in Nuremberg.

At booth 169 in Hall 7, we’ll demonstrate live how oxide layers can be removed automatically and inline, and how our PlasmaPlus® coating technology effectively prevents delamination during overmolding. Visit us on-site and discover what future-ready surface treatment looks like – precise, cleanroom-compatible, and environmentally friendly.

Challenges in Semiconductor and Power Module Production

Tough Demands on Materials and Interconnections

High-performance power modules must operate reliably for years under extreme conditions. Whether in electric vehicles, wind turbines, or industrial drives, these components are exposed to high temperatures, high voltages, and intense mechanical stress – all within increasingly compact designs.

A particular challenge lies at so-called “triple points,” where different materials such as copper, ceramics, and potting compounds meet. These zones are prone to stress, trapped air, or adhesion failure – all of which can shorten the module’s lifespan. One of the root causes: oxidized metal surfaces that compromise solderability and increase contact resistance. Epoxy delamination during overmolding is another common risk. To address these issues, reliable interconnect technology and targeted surface treatment are essential.

Live Demo at PCIM Europe

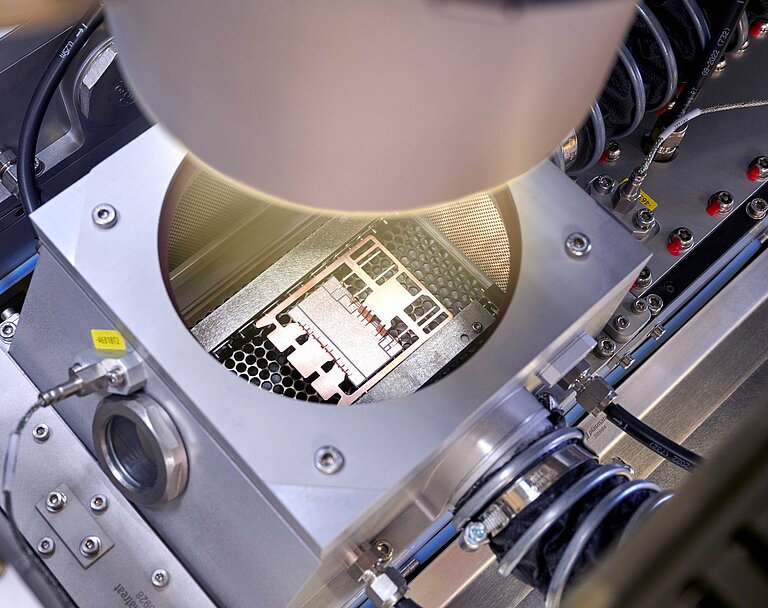

Experience our plasma technology live at booth 169 in Hall 7. In a fully automated demo cell, we’ll showcase both REDOX-based inline oxide reduction and functional nanocoating with PlasmaPlus® – all under realistic production conditions.

A highlight of our exhibit is the robot-controlled Plasma Treatment Unit (PTU), which allows for accurate, non-contact treatment of even complex geometries. At our interactive plasma demonstration table, you can see and feel the effects of plasma treatment for yourself – from surface cleaning and activation to improved wettability.

Our on-site experts are available to advise you on how our technologies can be tailored to your specific applications and processes.

Use Cases – Where Plasma Makes the Difference

Application Areas Across High-Demand Industries

Our plasma systems are used wherever power modules are exposed to extreme conditions and need to perform reliably. Different industries face different challenges – but the solution remains the same: advanced surface treatment with Openair-Plasma® and PlasmaPlus®.

E-Mobility

In inverters, battery management systems, and charging units, plasma ensures stable electrical contacts and prevents delamination in highly dynamic environments with intense heat and current loads.

Renewable Energy

Photovoltaic and wind energy systems require long-term durability despite exposure to UV radiation, moisture, and temperature swings. Plasma coatings help protect critical contact areas and improve reliability.

Industrial Automation

Power modules in industrial and robotic systems must withstand vibration, dust, and harsh media. Plasma treatment improves adhesion of potting compounds and ensures long-lasting, high-integrity connections.

The Exhibition Warm-Up: Power Module PlasmaTalk Now Online

主な課題と影響:

はんだ接合部のボイド

- 熱および電気インピーダンス:ボイドは、はんだ接合部の熱伝導性と電気伝導性を低下させ、ホットスポットや抵抗の増加、過熱による故障を引き起こします。

- 機械的弱点:ボイドは接合部の強度を損ない、熱や機械的ストレス下でクラックや故障を誘発します。

金属表面の酸化

- 接着不良:酸化膜により材料間の接着が妨げられ、層間剥離や組み立て部品の機械的強度の低下を招きます。

- 一貫性のないはんだ付け:酸化膜がはんだ付け性に影響し、接合部の密着性を低下させます。

素材適合性

- 熱膨張の不一致:材料によって熱膨張係数は異なります。適切な表面処理と接着技術がないと、熱サイクルによって応力が発生し、剥離やクラックにつながる可能性があります。

- 化学的不適合:化学反応による性能低下や故障を防ぐため、材料を慎重に選択し、適切な処理をする必要があります。

フラックス残留物

- 汚染:フラックス残渣が電気ショートや腐食を引き起こし、信頼性の問題につながる可能性があります。

- 洗浄の課題:部品が小型化し、高密度になるにつれて、部品を損傷することなくフラックス残渣を除去することは、ますます困難になっています。

小型化

- 精度の要件: 小さな部品や微細なピッチは、極めて精密な製造工程を必要とします。わずかな欠陥でも、重大な性能問題や故障につながる可能性があります。

- 放熱:部品のサイズが小さくなるにつれて放熱が難しくなり、高品質なはんだ接合と材料による効果的な熱管理が求められます。

長期信頼性

- 環境への暴露:パワーエレクトロニクスは、高温、湿度、振動などの過酷な環境にさらされるため、さまざまな材料と接合部のボイドや欠陥を削減するプロセスは長期的な信頼性を維持するために非常に重要です。

- 経年劣化:時間の経過とともに、材料は劣化し、接合部は弱くなります。ボイドや欠陥はこのプロセスを加速させ、早期の故障につながります。