Headlights – Tightly Sealed, Cost-Saving Bonding

Modern headlights using LED technology last for the lifetime of the vehicle, thus eliminating the need to change bulbs. To ensure this longevity, they must be effectively protected to keep all moisture out. When bonding headlights and tail lights made of polypropylene (PP) and polycarbonate (PC), the adhesive must therefore have excellent sealing properties as well as providing reliable adhesion.

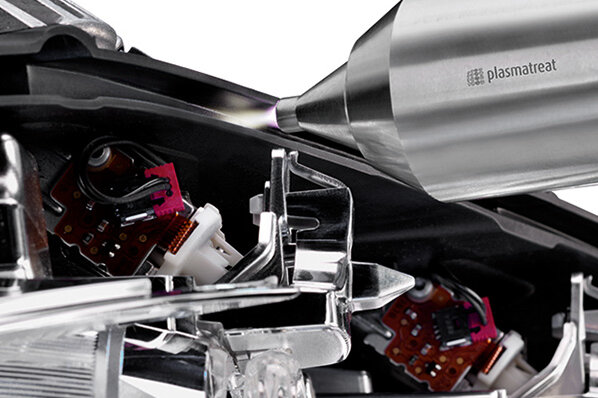

Precise localized pretreatment with Openair-Plasma® activates the non-polar materials in all critical areas, ensuring reliable bonding and long-term sealing of the headlights.

Topics on this page:

The high degree of plasma activation and the accuracy of the monitoring functions and fault diagnostics assure us the provision of a high-quality product.

Openair-Plasma® pretreatment of headlights is one of the most successful industrial applications of plasma technology. Headlight manufacturing would be unthinkable today without this technique. All leading manufacturers of headlights use Plasmatreat’s Openair-Plasma® technology.

Plasma integration into production line. Alternative to corona & flame pretreatment.

Thanks to its robot controlled inline technology, the Openair-Plasma® process integrates very easily into headlight manufacturing lines.

The special characteristics of Openair-Plasma® mean that the surfaces treated are not exposed to electric discharges as they would be with corona pretreatment, for example. With plasma pretreatment, the temperature increase in the materials being processed is very slight (as opposed to flame pretreatment). Chamber systems, such as required with low-pressure plasma treatment, are not needed.

The delicate and electrically conductive reflectors of the headlights can be pre-assembled and are not affected by plasma pretreatment, since this process is potential-free.

Hella: Surface treatment of headlight housings

Plasma treatment of headlight housings with complex geometries at Hella Australia prior to adhesive bonding. The contour-true, robot-controlled inline treatment makes it possible to achieve high process speeds.

Adhesion Improvement by Plasma Treatment before bonding, warm melt adhesives

The Openair-Plasma® process makes it possible for the first time to achieve reliable results when using newly developed one-component warm-melt polyurethane (PUR) adhesives on non-polar plastics, such as polypropylene. Pretreatment with Openair-Plasma® generates the required high surface tension on the materials to be bonded.

The technique for combining Openair-Plasma® with warm melt adhesives was successfully developed in collaboration with adhesives manufacturer Sika.

ADVANTAGES &

PROPERTIES

Warm melt adhesives

- High green strength

- Fast inline leakage testing

- Increases productivity (>15%)

Interesting success stories in this field

Microfine cleaning and coating of polycarbonate headlight covers

In order to protect the headlamps from stone-chipping, polycarbonate (PC, PMMA) headlight lenses need to have high surface hardness. For this reason, headlamp surfaces are usually coated with a scratch-proof, UV-cured paint (often using an acrylic polymer). These protective scratch-proof coatings offer up to 40 times more resistance against physical impact compared with uncoated lenses.

Microfine cleaning with Openair-Plasma® prior to paint finishes

The use of Openair-Plasma® rotary jets enables efficient and gentle microcleaning of polycarbonate headlight covers prior to coating them with paint finishes.

Plasma cleaning removes particles (dust, pigments, etc.) still adhering to the surface after the injection molding process. At the same time, it ensures that the lens is electrostatically discharged. Anti-static blowers are no longer required.

The specific and uniform surface tension achieved results in optimal distribution and uniform thickness of the subsequently applied coating layer. Openair-Plasma® thus significantly decreases reject rates.

Long-term scratch-proof coating with the low-pressure plasma method

As an alternative to hard coating, scratch-resistant and durable plasma coatings can be applied to the lenses. These coatings are applied using low-pressure plasma (i.e. a chamber plasma process), which increases the durability of these hard surface coatings on polycarbonate. The low-pressure plasma causes functional chemical groups to be embedded into the surface, resulting in a more cross-linked coating. Low-pressure plasma treatment with Plasmatreat can improve the surface hardness of some common materials by a factor of 100.

FEATURES

Plasma Coatings

- Nano-scale coatings

- Excellent optical characteristics

- More Stable

- Highly durable

- Easy-to-clean

- Surfaces many times harder than glass

Fogging in LED headlamp housings

Using LED bulbs in automobile headlamps generates less heat inside the headlamp housing. While this has several benefits, this also effects the humidity of the air inside the headlamp housing which could lead to fogging and condensation. Fogging causes the emerging light to refract differently and can have an adverse effect on the performance of the headlamp.

Anti-fog coating of interior surfaces in automobile headlamps using the low-pressure plasma process

The headlamp fogging problem has been solved by applying an anti-fogging polymeric coating to the inside of the headlamp assembly.

Plasmatreat has acquired extensive know-how in depositing anti-fog coatings using the low-pressure plasma (Aurora) process. Building on this experience, it has now become possible to apply this anti-fog coating using atmospheric plasma (Openair-Plasma®) as well. The anti-fog coating process can be integrated easily in existing production lines for high speed production of automobile headlamps.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

productronica

Hall A2, booth 445

Trade Fair Center Messe München

Munich

Germany

SEMICON Europa

Hall/Booth B1136

Messe München

Am Messesee 2, 81829 Munich

Germany

EUROGUSS

Hall 6, Booth 219

Nürnberg Messe

Messezentrum

90471 Nürnberg

Germany